Product Categories

Contact Us

Engineering Machinery Pin

The pin is a key component for achieving the rotational movement of mechanical parts, typically a cylindrical rod that works with the hinge seat and connecting plate to form a revolute joint. Its design emphasizes surface hardness and wear resistance; common materials include carbon steel (quenched and tempered), stainless steel (corrosion-resistant), and alloy steel (high-strength).

Keywords:

Description

Product Description

Spacer Bush/Shaft Sleeve/Bushing/Pin, though structurally simple, play a core role in mechanical systems by providing protection, support, and connection.

When selecting these materials, consider the specific application requirements: choose metal for high loads, plastic or stainless steel for corrosive environments,

and elastic rubber or self-lubricating composite materials for vibration scenarios. With the advancement of industrial automation and new energy technologies,

lightweight, self-lubricating, and long-lasting materials (such as polyurethane and nanocomposites) will become mainstream, driving mechanical components

towards higher efficiency and lower maintenance.

Applications:

Spacer Bush/Shaft Sleeve/Bushing/Pin are commonly used in industrial machinery, automotive transportation, aerospace,

new energy and environmental protection equipment, etc.,

playing a key role in mechanical connection, transmission support, wear protection and joint rotation scenarios.

Production Specifications

Materials: 20#, 45#, bearing steel, 42CrMo steel, stainless steel

Tolerance of Dimensions: ±0.01mm (1 silk = 0.01mm)

Hardness: 63 (the unit of hardness is not specified here, usually it could be HRC, such as 63HRC for Rockwell hardness)

Surface chrome plating and other treatments are also available.

Our advantages:

With the rapid development of the global infrastructure construction industry, there is a strong demand for construction machinery parts.

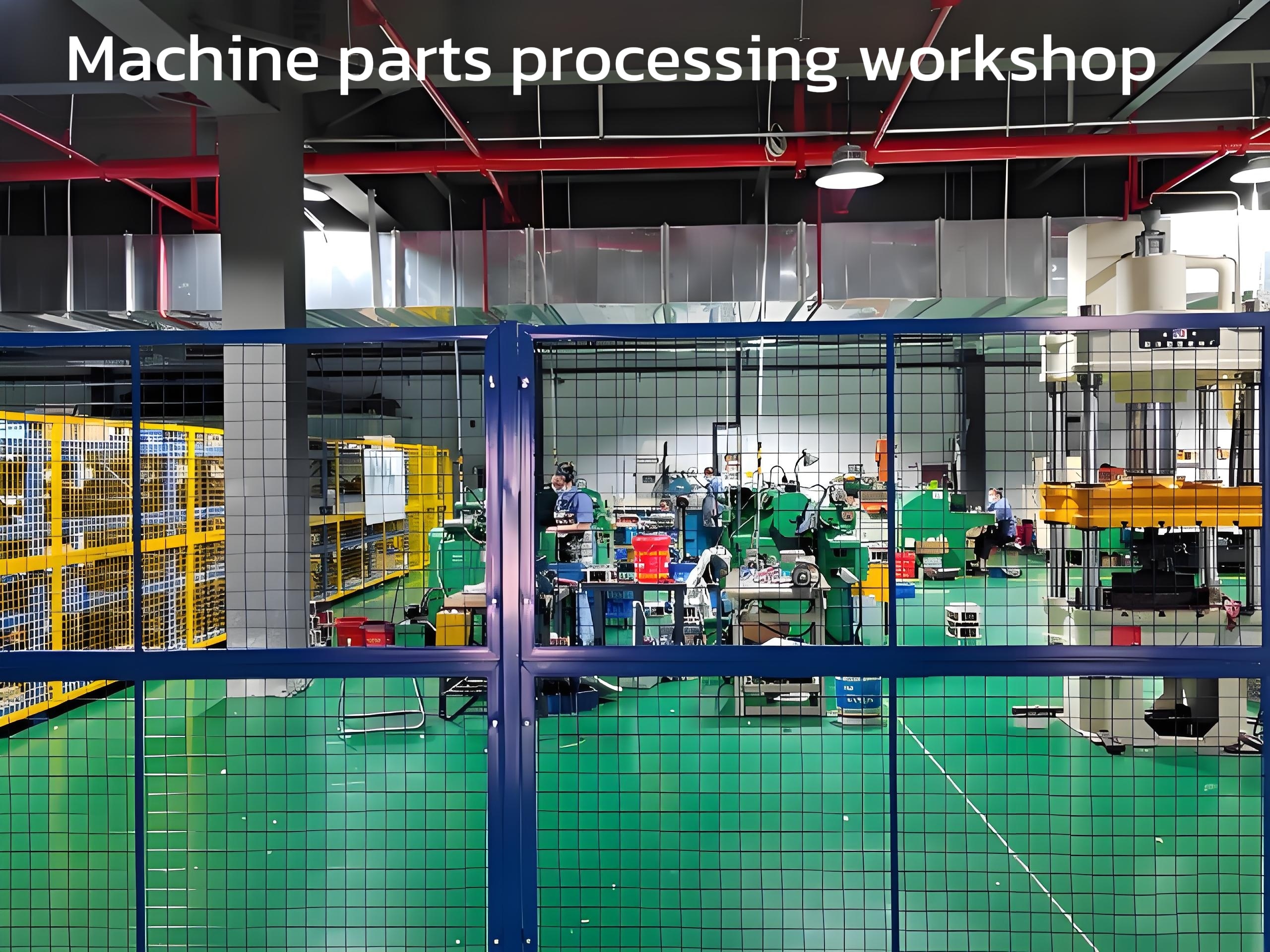

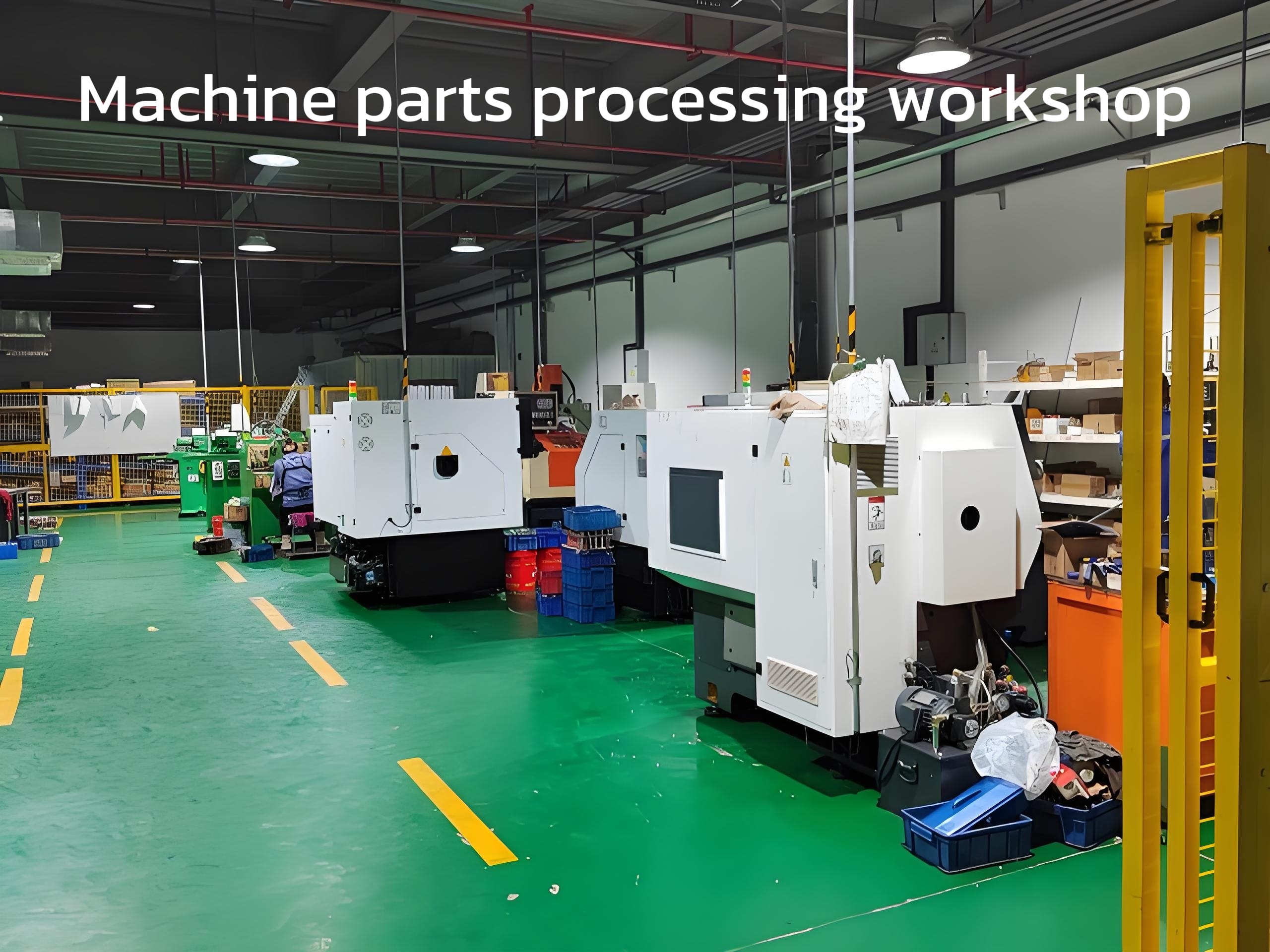

To make the most of our factory's advantages in the steel pipe industry, our factory established a new production workshop for

shaft sleeves in 2015. The production process covers lathe processing, heat treatment, carburizing, grinding, and finished product packaging.

This not only enables excellent quality control but also reduces the product cost, presenting obvious advantages.

Currently, our products are in short supply due to high demand.

Parameter

|

Product name |

Spacer Bush/shaft sleeve/bushing/pin |

|

Grade |

20#, 45#, bearing steel, 42CrMo steel, stainless steel ASTM 1020, ASTM 1045,ASTM 4140,stainless steel,bearing steel |

|

Surface treatment |

Galvanized,Black and color painting,Transparent oil,anti-rust oil or according to clients requirements |

|

Diameter in mm |

10-219 mm or customer required |

|

Diameter in inch |

0.394 to 8.62 inch or customer required |

|

Ends |

glazed or customer required |

|

OEM |

OEM available ,follow customer requirements |

|

Packing |

Bundle, or with all kinds of colors PVC or as your requirements |

|

MOQ |

5 pcs |

|

Lead Time |

within 15-30 days after received deposit or irrevocable L/C at sight |

|

Sample |

NO Free sample available |

|

Payment Term |

T/T or L/C at sight |

|

Production ability |

100000PCS per year |

Certificates

Factory equipment

Application

Packing & Delivery

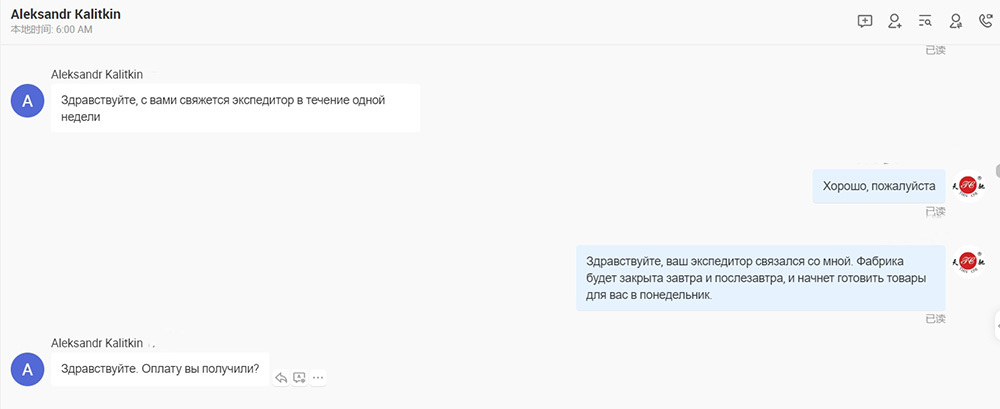

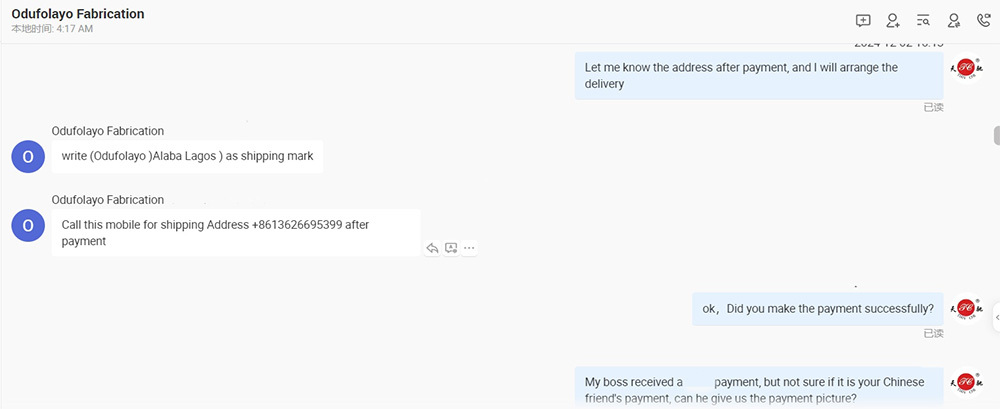

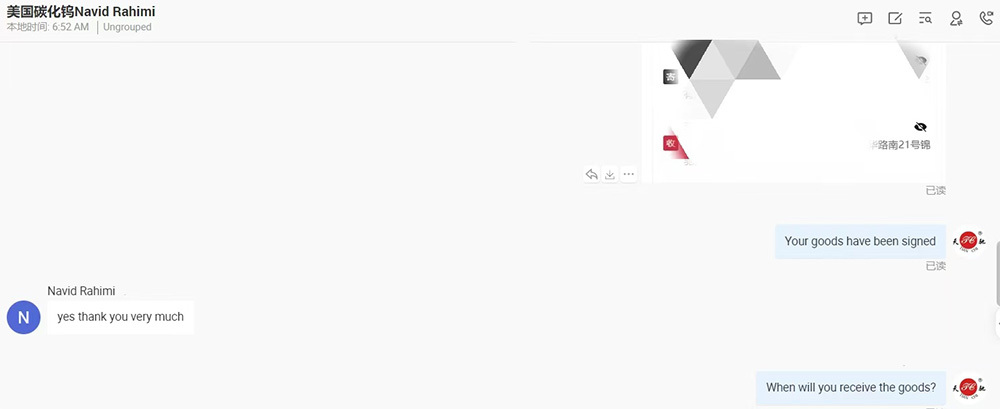

Communicate

FAQ

...

What product information do I need to provide?

It's my first time to import steel products, can you help me with it?

What about product prices information?

What ports of shipment are there?

Get a free quote

Please fill in the contact information with your needs, we will arrange a professional to contact you!